|

The Dark Side of Engineering: It’s Efficiency

|

As engineer I know too well how much we are tempted by the blank paper of a new project. After all we are “innovators” and tend to prefer effectiveness over efficiency.Dear Fellow Innovator, We shall admit our sins. We love to innovate. We love it so much that sometime we forget to assure that our ideas are not only effective, but also that they are created in an efficient way. If we narrow down our attention to the “creative section” of our companies: “the Engineering”, we may discover that “Efficiency” is not one of the top priorities. No wonder: a massive curtain of “math’s and jargons” assures any Engineering Office a shelter against a simple request of “productivity” that would be considered minimal and mandatory in a manufacturing or sourcing environment. The strange thing here, is that focusing a bit of attention on “Engineering Efficiency” would generate immediate and tangible results in at least 3 key business KPI: 1) Time to market: a more efficient engineering process can shrink delivery time 2) Cost of Quality: a more efficient engineering process can systematically detect and correct “random errors”. 3) Business Risks: a more efficient engineering process can assure greater precision in budgeting and multiply the possible solutions of the offering.

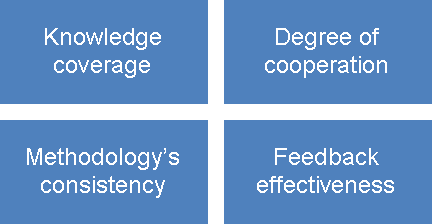

But how to inject Efficiency into Engineering? Here I want to propose a very high level framework that can help isolate 4 different “Engineering Efficiency Drivers” |

|

Little nightly thoughts by Business Exploration® |

|

—————————

If you are interested to know more, Just give me a call at +39 349 648 2225 or visit: EU Enginering - la buona ingegneria Cordialmente, Flavio© 2015 Business Exploration® - All Rights Reserved |

|

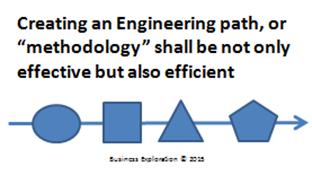

I will go through each of them, but before, let’s fix some definition: Engineering Goal: “transform customer’s problems into solution’s instructions”. Goal of the Engineering function is to create the instructions to build the solution to a Customer’s Problem. Engineering Efficiency: instructions per unit / Cost of quality / Time to issue. Engineering efficiency is defined as “instructions” produced per resource’s unit , reduced cost of errors and poor quality, reduced lead time / time to issue.

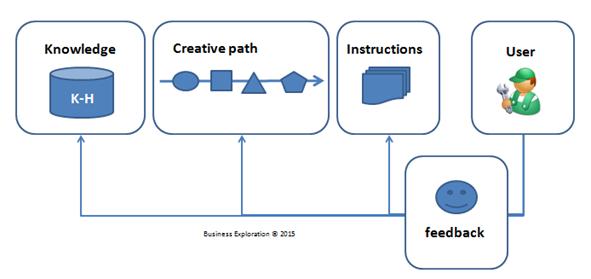

Based on this, we may think that the Engineering throughput is based on the ability of the Engineering function to: 1. Possess know-how 2. Make each of its members fully cooperate to build the path to the “instructions” 3. Be able to re-use that path, avoiding the costs to re-invent it. 4. Assure a feedback of the results that can be used to improve the first 3 points.

|

|

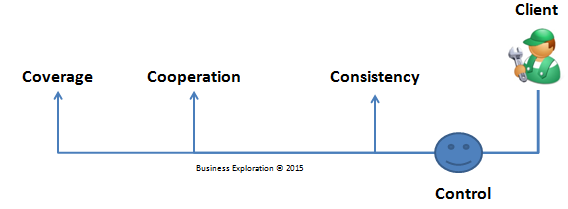

Let’s review each Engineering Efficiency Driver one by one:

1) Knowledge Coverage - the more you know, the better -

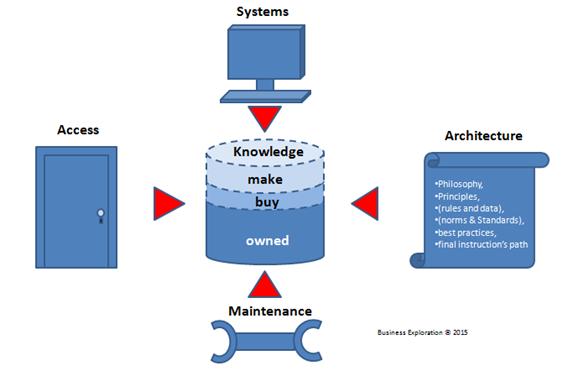

There are 3 elements of the “knowledge coverage”:

A) Owned Know-How All K-H owned by the Engineering team is the base of its ability to find a solution B) Searched Know-How The K-H not owned by the Engineering team shall be either reached outside the engineering team (BUY) or created by a dedicated activity (MAKE) C) Know-How Management Possessing the know-how is not sufficient, it must be used and therefore managed. There are 4 key elements of k-h management: i) Access To use K-H, Engineering must ensure Access to it. Doing it with security, weighting risks, etc., is part of managing the Access points . ii) Architecture Engineering team shall be able to “navigate” the K-H and to recover it. It’s not only a problem of “search” but also of priority: e.g.: philosophy, principles, (rules and data), (norms & Standards), best practices, final instruction’s paths iii) Systems Supporting systems are based on: processes, tools, resources, constrains iiii) Maintenance A Knowledge base shall be maintained: made available, made reliable, maintained up-to-date |

|

2) Degree of cooperation: the more Engineers cooperate, the better

The moment Engineers work together to identify and formalize a new path (methodology) to produce the solution’s instructions is of paramount importance.

But:

Is not about: Collaboration: A matter of friendly environment, teambuilding, culture or feelings

Is not about: Coordination: Performances, processes, tools, resources and constrains

Is about: Cooperation: Work together to put colleagues in the best conditions so to produce collectively the best results: both in terms of an effective path and of an efficient path. |

|

The Dark Side of Engineering: It’s Efficiency |

|

3) Methodology’s consistency: the more the methodology is repeatable – the better

There are two side of “consistency”: preparation and execution:

A) assure that the Engineering path has at least 4 attributes:

Consistent: all discretionalities, ambiguities and options iare solved within the path,

Coherent: the engineering path shall be coherent with the know-how Architecture ( see Driver n. 1)

Simple: as a minimum should take into account: openness to modifications, modularization, Lean compliant...

Call-able: findable, trackable, retrievable

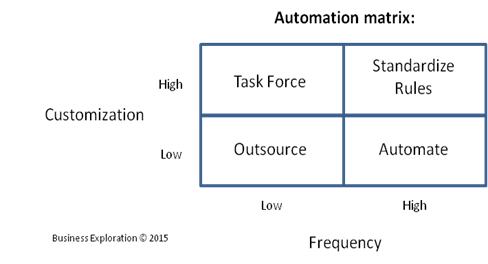

B) identifying opportunity for re-usage and automation:

Here the Customization / frequency matrix can be of help:

|

|

4) Feedback effectiveness: the more the lessons learned are embedded – the better

There can not be improvement in coverage, cooperation, consistency:

if there is not a feedback loop of lessons learnt capable to:

· Embed external experiences · Refine the existing status · Systematically correct mistakes

|

|

This 4 Drivers Framework, is used by me, in cooperation with my partner Claudia Miani and the software house

to help equipment manufacturers shed light on the Dark Side of the Engineering:

· In the Commercial phase: streamlining the customization process · In the Engineering phase: avoiding “reinvent the wheel” activities · In the Supply chain phase: systematically killing costs of quality

|

|

Read more about marketing innovation, Ask our free booklets: here |

|

If you need more Engineering Efficiency:

|

|

Check out or Knowledge Management methodology EU-Engineering |

|

Our Newsletter reaches 2200 professionals in 47 nations, with the ambition to offer alternative points of view and a relax break to our readers. |